On June 9, 2024, Protolabs released the 2024 edition of its yearly 3D Printing Trends Report, which presents 3D printing trends and the future of 3D printing; repainting a positive picture for the international 3D printing sector, highlighting market growth, ecosystem maturation, and new modern technology innovations.

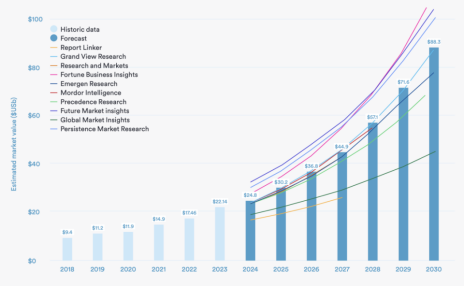

(Protolabs Trends Report 3D Printing Market Growth and Forecast.Source: Protolabs)

The report, based on key market data and understandings from more than 700 design experts, mirrors self-confidence in the additive production market. New mini and big applications and the growing capacity of 3D printing for end-use component production range are reported to be driving this trend.

The 3D printing sector is stated to be expanding 10.5% faster than expected. The market size is reported to expand at a compound annual development price of 21% to $24.8 billion in 2024 and is expected to get to $57.1 billion by the end of 2028.

This 3D printing market valuation is consistent with information from market knowledge company Wohlers Associates, which forecasts the market will deserve $20 billion in 2024.

On top of that, the record mentions that 70% of firms will certainly 3D publish more components in 2023 than in 2022, with 77% of participants pointing out the clinical sector as having the best capacity for impact.

“3D printing is now securely established in the production industry. The market is maturing as it comes to be a much more widely used commercial production process. From style software to automatic manufacturing services to boosted post-processing methods, this emerging community shows that more and more firms are utilizing production-grade 3D printing,” according to the record.

Application of round tantalum powder in 3D printing

The application of spherical tantalum powder in 3D printing has actually opened a brand-new phase in new products science, especially in the biomedical, aerospace, electronics and accuracy machinery markets. In the biomedical area, round tantalum powder 3D published orthopedic implants, craniofacial repair frameworks and cardiovascular stents give people with more secure and extra personalized treatment options with their outstanding biocompatibility, bone combination ability and deterioration resistance. In the aerospace and protection market, the high melting point and security of tantalum products make it a perfect choice for producing high-temperature parts and corrosion-resistant parts, guaranteeing the trusted operation of equipment in extreme atmospheres. In the electronic devices industry, round tantalum powder is used to produce high-performance capacitors and conductive finishings, satisfying the demands of miniaturization and high capability. The benefits of round tantalum powder in 3D printing, such as good fluidity, high density and easy blend, ensure the accuracy and mechanical properties of printed components. These advantages come from the consistent powder dispersing of spherical fragments, the ability to minimize porosity and the little surface get in touch with angle, which with each other advertise the thickness of printed parts and decrease problems. With the constant innovation of 3D printing technology and material science, the application potential customers of round tantalum powder will certainly be more comprehensive, bringing revolutionary adjustments to the premium production sector and advertising ingenious breakthroughs in fields varying from medical wellness to sophisticated technology.

Vendor of Round Tantalum Powder

TRUNNANO is a supplier of 3D Printing Materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about tantalum metal powder, please feel free to contact us and send an inquiry.

Inquiry us